US Inverter Control Booster Pump System(Simplex)

1.It will not have unstable water pressure. The water pressure will stay constant all the time. It improves the drawback that differential pressure controller would cause. It will not cause water hammer effect due to old pipeline structure. You can set up whatever pressure is necessary for the sites.

2.Low and smooth operating noise. It will adjust motor speed and frequency according to current demand for water. It will save electricity and maintain longer life expectancy for the pump.

3.Customized design for customers if they want to choose different bladder capacities, pump models, inverters or pump quantities for alternate or parallel operations.

4.Silent operation and constant pressure.

5.Easy installation without cooling tower. You don't have to worry about periodic maintenance for cooling tower.

6.Adopting high quality "Delta" inverter and "Danfoss" pressure transmitter that provide better stability for the system.

7.It will automatic switch off within 20 seconds for dry-running situation. The motor will not burn out easily. If dry-running incident occurs, it will auto re-start every 20 minutes until the water source is completely back to normal.(You can adjust automatic reset timing according to your needs.)

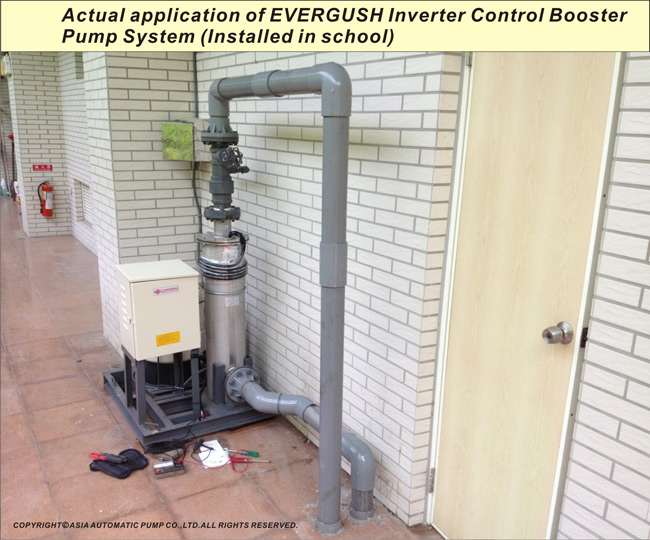

Auto boost water pressure for IC manufacture industries, industrial pressure boosting systems, motels, restaurants, gas stations, apartments, factories, schools, parks, gymnasiums, villas, railway station,

building sites, etc.

1.Ambient temperature: 0~+50℃

2.Liquid temperature: +0~+60℃ (If liquid temperature is over 60℃,we will change it to heat-resistant mechanical seal and bearing)

3.Clean or potable water or no corrosive chemicals liquids without abrasives

4.Working pressure: Max. 10~20 bar.(Different pumps have different pressure resistant)

1.Horsepower: 1/2HP~20HP

(Above 20HP specification are available upon customer's special request)

2.Protection: IP54~55

3.Insulation: E,B,F

4.R.P.M.: 2P,4P

5.Voltage: 1 phase 110;220V*60HZ(Below 3HP); 3 phase 220/380/440/660*60HZ

1 phase 220~240V*50HZ(Below 3HP); 3 phase 380~415V*50HZ

6.Suction/Discharge: 1” ~10”

7.Head: Max. 260 M

8.Capacity: 3.5~240M³/hr.